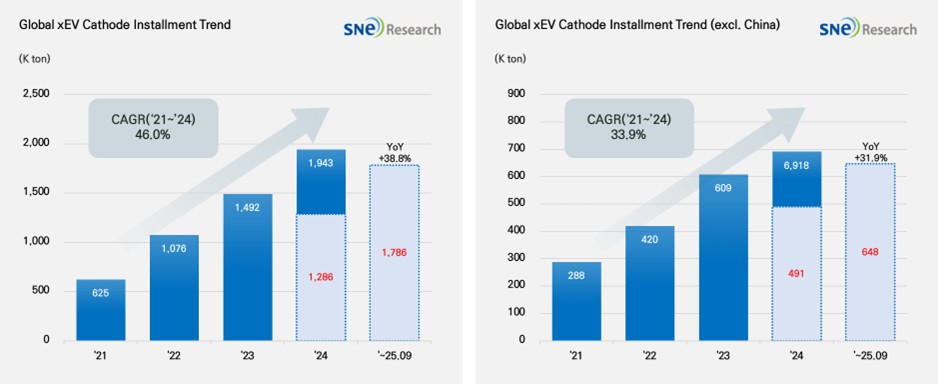

From Jan to Sep 2025, Global[1] Electric Vehicle Battery Cathode Material Installment[2] Posted 1,786K ton, a 38.8% YoY Growth

- From Jan to Sep 2025, EV battery cathode material

installment in non-China market was 648K ton, posting a 31.9% growth

(Source: 2025 Oct Global EV & Battery Monthly Tracker (Incl. LiB 4

Major Materials), SNE Research)

From Jan to Sep 2025, the total installment of cathode materials used in electric vehicles (EV, PHEV, HEV) registered worldwide was approx. 1,786K ton, posting a 38.8% YoY growth. If we look at the market except China, the total cathode usage was 648K ton, and the growth rate was 31.9%, which was steady and stable. Cathode material is a key material determining the capacity and output value of lithium-ion battery, upon which the performance of battery and driving range of electric vehicles depend. Currently, the battery market can be divided into the one centered around NCx ternary cathode material and the other mainly led by LFP cathode material, and both are driven by technical and economic advantages of each cathode material. Amidst the diversification of global cathode material demand, NCx ternary cathode material and LFP cathode material are positioning themselves as two main axes in the market.

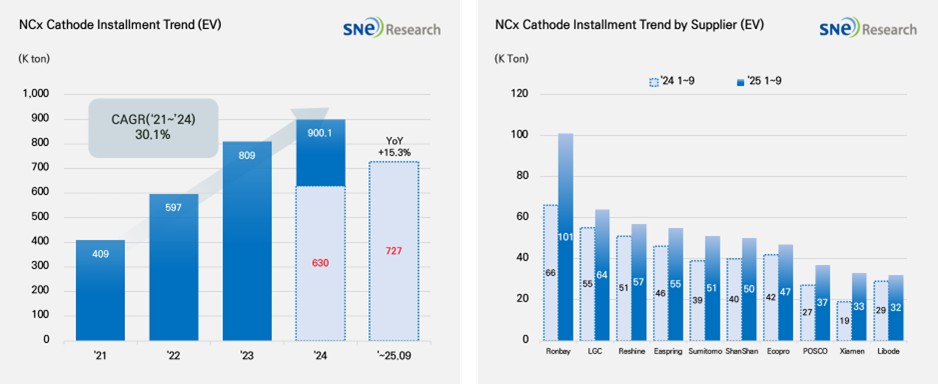

If we look at the market by different cathode materials, the installment of ternary cathode material during the relevant period was 727K ton, posting a 15.3% YoY increase and continuing a gradual growth. By company, Ronbay and LG Chem ranked 1st and 2nd on the list, leading the market. L&F (63K ton), Ecopro (47K ton), and POSCO (37K ton) all entered the upper rank, maintaining their reputation as leading Korean suppliers in the market. Overall, however, the growth of Chinese cathode material makers showed a noticeable growth. Major cathode suppliers such as Reshine, Easpring, and ShanShan are competing fiercely, and the Chinse cathode makers are gradually expanding their global market shares based on demand from the Chinese domestic market, price competitiveness, and their massive ramp-up plans.

(Source: 2025 Oct Global EV & Battery Monthly Tracker (Incl. LiB 4 Major Materials), SNE Research)

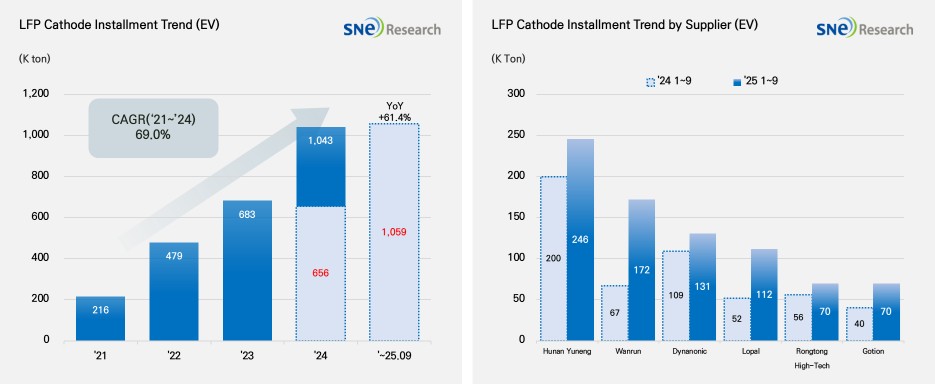

During the same period, the total installment of LFP cathode material was 1,059K ton, showing a rapid growth of 61.4% compared to the same period last year. In terms of growth pace, LFP cathode material surpassed that of ternary cathode material. Among the total cathode material installment, the proportion taken by LFP was about 59% (based on weight), meaning that the usage of LFP material has an increasing influence on the market. It is interpreted as being affected by the expansion of entry-level EV market in China, increasing preference to LFP chemistry with price competitiveness, and increasing adoption of LFP batteries by global OEMs. By cathode suppliers, Hunan Yuneng (246K ton) and Wanrun (172K ton) ranked 1st and 2nd on the list, while Dynanonic (131K ton) and Lopal (112K ton) took the 3rd and 4th places based on their growth higher than that of last year. Given the fact that the upper ranks are all taken by the Chinese companies, it is obvious that the LFP cathode material market is dominated by the Chinese companies. In turn, the growth of LFP cathode material market is directly connected to the reinforcement of global dominance by the Chinese material companies, which ultimately leads to solidify the China-centered structure in the global supply chain for battery materials.

(Source: 2025 Oct Global EV & Battery Monthly

Tracker (Incl. LiB 4 Major Materials), SNE Research)

In 2025, the cathode materials market has entered a transition phase, marked by the rapid rise of LFP and the technological advancement of ternary (NCM/NCA) materials. As of January–September, LFP accounted for roughly 60% of total demand, expanding its dominance, while high-nickel materials continue to see solid demand in the high-performance EV segment. Since October, developments such as Toyota and Sumitomo’s joint R&D on solid-state battery cathodes and BASF’s supply of semi-solid cathode materials have clearly indicated the direction of next-generation technology transition. Meanwhile, China’s temporary suspension of battery material export controls has provided short-term stability, but a future reinstatement of such measures could rekindle global supply chain uncertainty. Ultimately, the focus of competition is expected to shift from capacity expansion to securing high–energy-density and high-safety material technologies, alongside building regionally independent value chains.

[1] The xEV sales of 80

countries are aggregated.

[2] Based on batteries installed to electric vehicles registered during the relevant period.