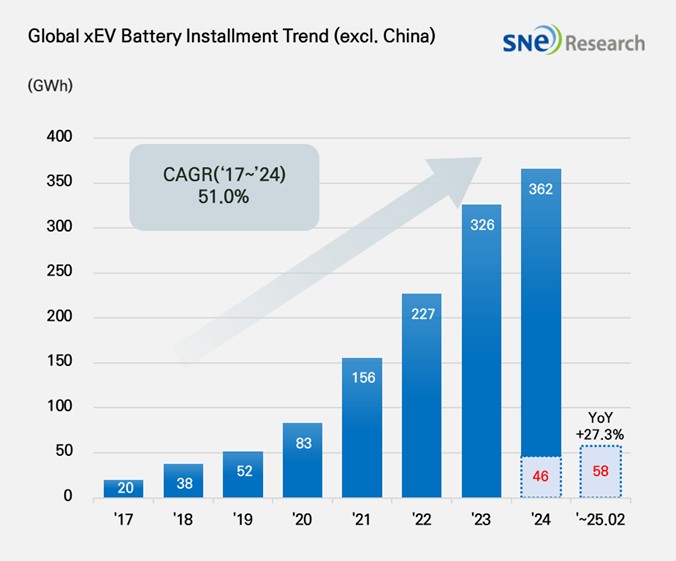

From Jan to Feb 2025, Non-Chinese Global[1] EV Battery Usage[2] Posted 58.3GWh, a 27.3% YoY Growth

- From Jan to Feb 2025, K-trio’s combined M/S recorded 38.6%

Battery installation for global

electric vehicles (EV, PHEV, HEV) excluding the Chinese market sold from Jan to

Feb 2025 was approximately 58.3GWh, a 27.3% YoY growth.

(Source: Global EV and Battery Monthly Tracker – Mar 2025, SNE Research)

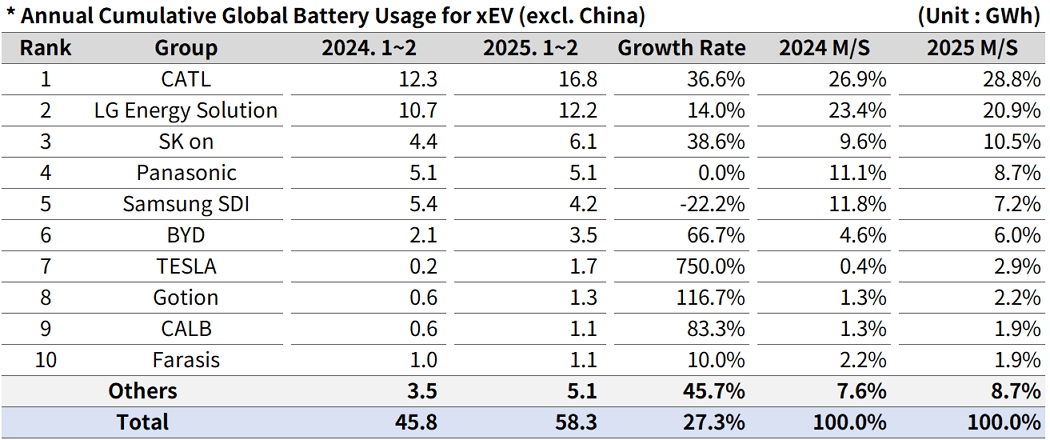

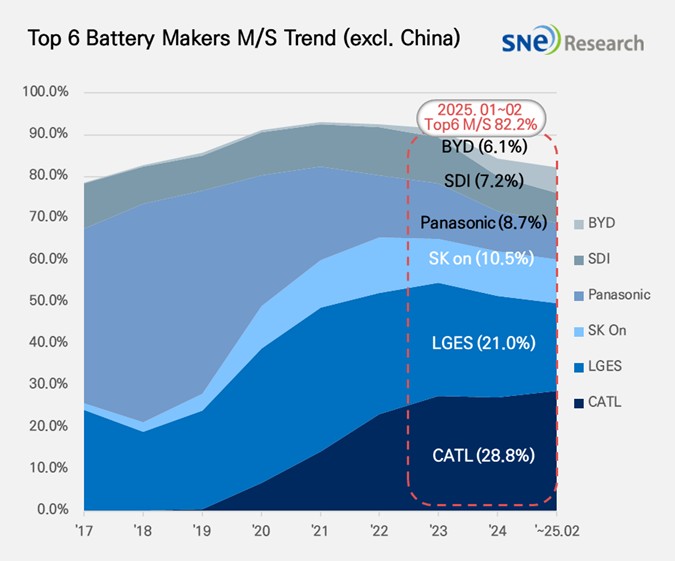

The combined market shares of LG Energy Solution, SK On, and Samsung SDI in global electric vehicle battery usage from Jan to Feb 2025 posted 38.6%, a 6.2%p decline from the same period of last year. LG Energy Solution remained 2nd on the list with 14.0%(12.2GWh) YoY growth, while SK On ranked 3rd with 38.6%(6.1GWh). On the other hand, Samsung SDI posted a 22.2%(4.2GWh) degrowth. The downward trend in Samsung SDI’s battery usage was mainly caused by a decline in demand for batteries from major car OEMs in Europe and North America.

(Source: Global EV and Battery Monthly Tracker – Mar 2025, SNE Research)

If we look at the usage of battery made by the K-trio in terms of the sales volume of models, Samsung SDI’s battery was mainly used in BMW, followed by Audi and Rivian. BMW has Samsung SDI’s battery in its models such as i4, i5, i7, and iX, and among these, i5 released in 2023 sold well in the market. On the other hand, even though Rivian posted a steady sale of R1S and R1T in the US, the release of standard-range trim with LFP battery, made by a battery maker other than Samsung SDI, had a negative impact on the installment volume of battery made by Samsung SDI. AUDI saw a decrease in sales of Q8 e-Tron, leading to a 21.9% decline in the usage of Samsung SDI’s battery in vehicles made by BMW, VW, and Rivian.

SK On’s battery was mainly installed in EV models made by Hyundai Motor Group, followed by Mercedes-Benz and Volkswagen. Hyundai Motor Group saw a recovery in sales after the facelifted version of IONIQ 5 and EV 6 were released. Mercedes-Benz saw favorable sales of compact SUV EQA and EQB, to which SK On’s battery are installed, which was similar to the same period of last year. Along with this, solid sales of VW ID.7 and ID.4 also brought about a positive impact on growth of battery usage made by SK On.

LG Energy Solution’s battery was mainly used by Tesla, followed by VW, Chevrolet, and Kia. In case of Tesla, the sales decline of models equipped with LG Energy Solution’s batteries led to a 32.7% decrease in Tesla’s usage of LG Energy Solution’s batteries. Meanwhile, the total usage grew by 14.0% due to favorable sales of VW’s ID series and Kia’s EV3, and the expanded sales of Chevrolet Equinox, Blazer, and Silverado EVs, which are built on the Ultium platform.

Panasonic, which supplies batteries to Tesla, remained 5th on the list with a battery usage of 5.1GWh. As Panasonic’s battery usage is highly dependent on the sales of Tesla, the decline in sales of Model 3 and Y is analyzed as the main reason for decreasing sales of Tesla this year. Panasonic is expected to quickly recover its battery usage in North America, primarily for Tesla, by releasing improved 2170 and 4680 cells.

CATL accounted for the largest market share not only in the global market but also in the non-China market, growing by 36.6%(16.8GWh). Currently, major global OEMs such as VW, BMW, Mercedes, Hyundai Motor all adopt CATL’s batteries. In particular, CATL is expected to rapidly expand its global market share by addressing the issue of oversupply in the Chinese domestic market through exports to countries such as Brazil, Thailand, Israel, and Australia.

(Source: Global EV and Battery Monthly Tracker – Mar 2025, SNE Research)

Meanwhile, electric vehicle competition in emerging Asian markets is intensifying, as Hyundai Motor launches a region-specific model for Southeast Asia and Tata Motors unveils a new electric SUV in India. As a result, competition is expected to intensify with Chinese companies such as CATL and BYD, which have established LFP battery supply chains and localization strategies. Accordingly, Korean battery manufacturers are seeking response strategies by expanding cost-competitive battery products and strengthening local joint ventures. Furthermore, as the global electric vehicle market reaches a turning point driven by regional policy changes and the launch of new models, maintaining competitiveness through supply chain stabilization and tailored strategies has emerged as a key challenge for Korean companies.

[2] Based on battery installation for xEV registered during the relevant period.