<2025> Latest Status and Outlook of All-Solid-State Battery Electrolytes and Manufacturing Technologies

(In-Depth Analysis of Key Developers and Manufacturing Technologies of

Solid Electrolytes and ASSBs)

The

performance of lithium-ion batteries, which are currently the most widely used,

has continuously improved due to relentless technological advancements driven

by the surging demand for new electronic devices and electric vehicles.

Notably, energy density has dramatically increased to exceed 350Wh/kg. However,

higher energy density also entails a greater risk of fire and explosion.

Lithium-ion batteries can experience electrical failures, internal overheating,

and heat release due to mechanical damage, over-discharge, or overcharge,

potentially leading to thermal runaway and explosive reactions.

To

mitigate these risks, solid-state batteries, which incorporate solid

electrolytes, have emerged as a next-generation battery technology alternative.

The key advantages of solid-state batteries include excellent safety, high

energy density, high power output, a wide operating temperature range, and fast

charging. As a result, they offer freedom from explosion risks and can operate

safely and stably even in extreme temperatures, from sub-zero conditions to

high temperatures of 60–100°C. This enhances their applicability across a

broader range of fields.

According

to predictions by SNE Research, the global solid-state battery market size is

expected to grow to 122GWh by 2030, achieving a penetration rate of 1.6%. By

2035, it is forecasted to reach 493GWh, accounting for 6.1% of the total

battery market. Governments of countries including South Korea, the United

States, China, Japan, and various European nations are responding with

national-level support policies to secure and lead next-generation battery

technologies. In South Korea, for example, the government announced plans to

invest 117.2 billion KRW by 2028 through a program supporting three types of

next-generation batteries, including solid-state batteries, starting in the

second half of 2024.

To

prepare for the rapid shift in the paradigm of secondary batteries towards

solid-state batteries, proactive development of key materials and mass

production technologies related to solid-state batteries is essential. While

solid-state batteries have the potential to overcome the limitations of

existing batteries, several challenges remain, including ion conductivity,

interface stability, mass production technologies, and price competitiveness.

Meanwhile,

most companies predict that the commercialization of solid-state batteries will

occur around 2030. This timeline is influenced not only by the high cost of

solid electrolytes and the underdeveloped materials for commercialization, but

also by the lack of established manufacturing (production) technologies.

Therefore,

this report aims to predict the current level of manufacturing technologies

based on patents and various information, while addressing the issues related

to materials and process technologies required to manufacture solid-state

batteries. Additionally, it seeks to propose appropriate solutions to these

challenges.

Specifically,

through patent and paper analysis on solid-state batteries, the report

identifies the strengths of different countries in terms of application fields.

By analyzing the patents of major companies, it examines the manufacturing

technologies of each company. Furthermore, through a review of literature and

presentations on manufacturing technologies and methods, the report evaluates

the advantages and disadvantages of each approach and explores which

manufacturing processes are most suitable.

Strong

Points of This Report

1.

All-Solid-State Battery Technology Trends and Market Outlook

2.

Overall Issues with Solid Electrolytes and Proposed Solutions

3.

Cell Configuration and Considerations for Applying Solid Electrolytes in

Batteries

4.

Comparison of All-Solid-State Battery Cell Manufacturing Technologies and

Processes

5.

Manufacturing Technology Trends of Key Companies such as TOYOTA, HONDA, and SDI

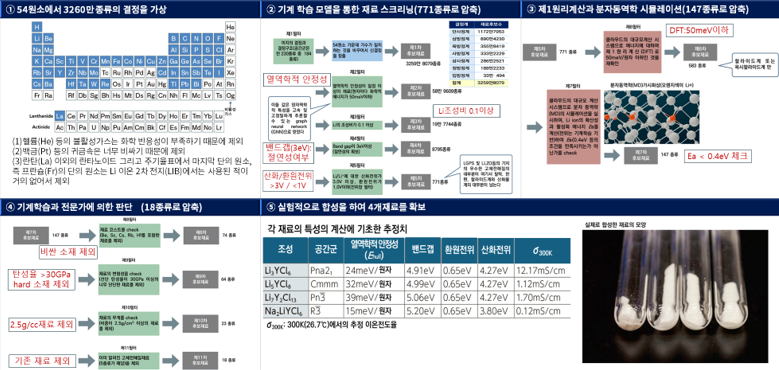

< Development of New Halide-Based Solid Electrolytes Using AI by PNNL-Microsoft >

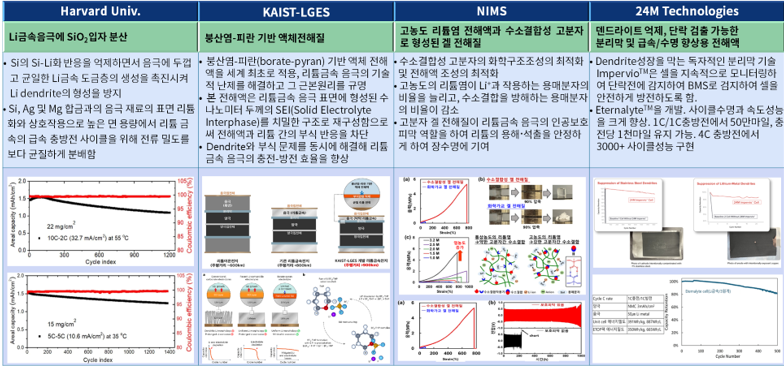

< Current Status of Technology Development for Improving the Lifespan of Li Metal Anodes >

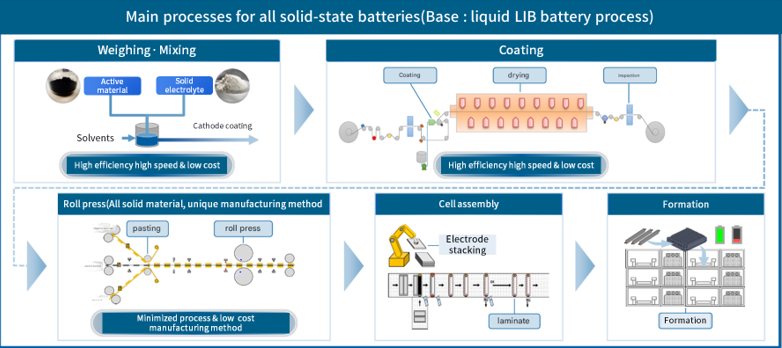

< HONDA's Solid-State Battery Manufacturing Process >

- Table of Contents -

- Overview of All-Solid-State Batteries (ASSBs)

1.1 All-Solid-State Battery (ASSB)

1.1.1 History

and Future of EV Development-------------------------------------------------------6

1.1.2 Technological Advancement and

Evolution of Batteries--------------------------------7

1.1.3 Limitations

of Lithium-Ion Secondary Batteries (LIBs) ------------------------------------9

1.1.4 Characteristics

and Necessity of ASSB Development ------------------------------------11

1.1.5 Application

Fields of ASSB ---------------------------------------------------------------------12

1.1.6 ASSB Industry Chain --------------------------------------------------------------------------24

1.1.7 Market Outlook of ASSB -------------------------------------------------------------------------25

1.1.8 ASSB

Patent Application Status ----------------------------------------------------------30

1.1.9 ASSB

Research Publication Status -------------------------------------------------------41

1.2 ASSB Technology Trends

1.2.1 Policies (projects) for

Solid-State and Next-Generation Batteries----------------------48

1.2.2 Mass

Production Status of EV Applications by Car OEMs ------------------------------51

1.2.3 Technology

Trends and Responses by Major Battery OEMs --------------------------52

1.2.4 Development and Response Status of

Material/Component Companies------------56

1.2.5 ASSB Production Status by Major OEMs-----------------------------------------------57

2. Solid Electrolytes

2.1 Solid

Electrolytes for ASSBs

2.1.1 Types and Compositions of Solid

Electrolytes---------------------------------------------60

2.1.2 Types and

Electrochemical Properties of Solid Electrolytes ----------------------------62

2.1.3 Li+ ion Conduction Mechanism in Various Solid

Electrolytes -------------------------63

2.1.4 Patent Application Trends in Solid

Electrolytes -------------------------------------------64

2.2 Oxide-Based Solid Electrolytes

2.2.1 Properties and Characteristics of

Oxide-Based Electrolytes----------------------------69

2.2.2 Ion Conductivity and Application Areas

of Oxide-Based Electrolytes-----------------70

2.2.3 Types of Oxide-Based Solid Electrolytes----------------------------------------------71

2.2.4 Advantages and Issues of Oxide-Based

Solid Electrolytes------------------------------78

2.2.5Solutions to Key Issues of Oxide-Based

Electrolytes----------------------------------79

2.3 Sulfide-Based

Solid Electrolytes

2.3.1 Characteristics of Sulfide-Based

Solid Electrolytes---------------------------------------80

2.3.2 Ion Conductivity and Applications of

Sulfide-Based Electrolytes----------------------81

2.3.3 Advantages and Disadvantages of

Sulfide-Based Solid Electrolytes----------------- 82

2.3.4 Comparison of Synthesis Methods for

Sulfide-Based Solid Electrolytes------------84

2.3.5 Structure of Sulfide-Based Solid

Electrolytes---------------------------------------------- 87

2.3.6 Overview and Characteristics of Argyrodites---------------------------------------------88

2.3.7 Overview and Characteristics of LGPS-----------------------------------------------------90

2.3.8 Overview and Characteristics of LPS----------------------------------------------------------93

2.3.9 Overview and Characteristics of Thio-LISICON--------------------------------------------95

2.3.10 Issues Related to Sulfide-Based

Solid Electrolytes--------------------------------96

2.3.11 Cost Comparison of LPSCl Using

Low-Purity Precursors------------------------------102

2.4 Halide-Based Solid Electrolytes

2.4.1 Properties of Halide-Based

Solid Electrolytes-----------------------------------------104

2.4.2 Characteristics of Halide

Electrolytes: High Li-Ion Conductivity----------------------105

2.4.3 Oxyhalide / Amorphous Structure----------------------------------------------------------106

2.4.4 Halide-Based Solid Electrolytes:

Enhancing Ion Conductivity -----------------------107

2.4.5 Development of New Solid Electrolytes Using AI

---------------------------------------109

2.4.6 Comparison with Other Solid

Electrolyte Materials--------------------------------------112

2.4.7 Oxyhalide-Based Solid Electrolytes --------------------------------------------------------113

2.4.8 Li3InCl6 Oxygen

Capture and Suppression, Safety Enhancement--------------------114

2.5 Polymer Solid Electrolytes

2.5.1 Types and Characteristics of Polymer

Matrices------------------------------------------116

2.5.2 Types and Advantages/Disadvantages of

Polymer Electrolytes----------------------117

2.5.3 Properties of Polymer Electrolytes------------------------------------------------------118

2.5.4 Issues with Polymer Electrolytes: Low

Conductivity, Stability, etc. ------------------119

2.5.5 Challenges and Solutions for Polymer

Electrolytes --------------------------------------120

2.6 Solid Electrolyte Compatibility

2.6.1 Key Considerations for ASSB Cells-----------------------------------------------------------121

2.6.2 Cathode-Electrolyte Compatibility

Issues----------------------------------------------122

2.6.3 Anode-Electrolyte Compatibility

Issues---------------------------------------------------123

2.6.4 Correlation Between Elastic Modulus

of Solid Electrolytes and Cell Performance-------------------------------------------124

2.6.5 Impact of Stack Pressure and Current

Density on Charge/Discharge----------------125

3. ASSB Electrodes

3.1 Cathode

3.1.1 Cathode Active Materials for ASSBs-------------------------------------------------------127

3.1.2 Cathode Active Material Trends---------------------------------------------------------------128

3.1.3 Development Trends of Composite

Cathodes for ASSBs-------------------------------129

3.1.4 Cathode and Composite Cathode

Processing ------------------------------------------130

3.1.5 Challenges in Composite Cathode

Development for ASSBs----------------------------133

3.1.6 Research on Surface Coating Materials

for Cathode Active Materials---------------134

3.1.7 Analysis of LPSCl-Coated NCM523

Cathode-----------------------------------------------136

3.1.8 Comparison of Electrode-Electrolyte

Interfaces with and Without Coating-------137

3.1.9 Various Cell Analyses After 50 Cycles---------------------------------------------------------138

3.1.10 Methods for Improving Cathode

Performance -------------------------------------------139

3.1.11 Recently Modified Cathode Active

Materials and Advantages------------------------140

3.2 Anode

3.2.1 Necessity of Anode Development for

ASSBs----------------------------------------------141

3.2.2 Technical Challenges in Anode Material

Development for ASSBs------------------142

3.2.3 Silicon Anode------------------------------------------------------------------------------------143

3.2.4 Si-C Anode-----------------------------------------------------------------------------------144

3.2.5 Research on Silicon-Based Anode

Materials------------------------------------------145

3.2.6 Processing of Lithium Metal and

Silicon Anodes--------------------------------------146

3.2.7 Lithium Metal Anode---------------------------------------------------------------------------148

3.2.8 Lithium Metal Anode Manufacturing

Process ---------------------------------------------149

3.2.9 Necessity of Thin Lithium Foil

Application-------------------------------------------------151

3.2.10 Research on Lithium Dendrite

Suppression and Interface Stabilization-------152

3.2.11 Development of Technologies to Extend

Lithium Metal Anode Lifespan----------154

3.2.12 Overview of Anode-Free Batteries---------------------------------------------------------155

3.2.13 Energy Density Comparison: Anode-Free

vs. Other Batteries------------------------156

3.2.14 Lithium Melt Deposition Process-----------------------------------------------------161

3.2.15 3D Grid Porous Li₄Ti₅O₁₂ Thick Electrodes-----------------------------------------------162

3.2.16 Recently Modified Anode Active

Materials and Advantages---------------------163

4. ASSB Cells

4.1 Manufacturing of ASSBs

4.1.1 Solid Electrolyte Processing------------------------------------------------------------------165

4.1.2 Cell Assembly------------------------------------------------------173

4.1.3 Cell Finishing--------------------------------------------------------175

4.1.4 Comparison of Manufacturing Processes:

ASSB vs. LIB----------------------------------176

4.1.5 ASSB Material Cost---------------------------------------------------------178

4.1.6 ASSB Cell Manufacturing Cost-------------------------------------------------------179

4.1.7 Promising ASSB Cell Concepts-------------------------------------------------------180

4.1.8 Fabrication of All-Solid-State Battery

(Semi-Solid-State Battery) Cells----------181

4.2 Oxide-Based ASSB

4.2.1 Most Promising Cell

Configurations ---------------------------------------------------------182

4.2.2 Considerations in Battery Structure----------------------------------------------------------183

4.2.3

Considerations in Battery Production------------------------------------------------------184

4.2.4

Key Performance Indicators-------------------------------------------------------------------185

4.2.5

Changes in Cell Concepts-------------------------------------------------------------------186

4.3 Sulfide-Based ASSB

4.3.1 Cell Configuration--------------------------------------------------------------------------------187

4.3.2

Considerations in Battery Structure-------------------------------------------------------188

4.3.3

Considerations in Battery Production------------------------------------------------------189

4.3.4

Key Performance Indicators--------------------------------------------------------------------190

4.3.5

Structure with Silicon Anode---------------------------------------------------------------191

4.3.6

Structural Considerations for Si/C Composite Anode Application-------------------192

4.3.7 Production Considerations for Si/C

Composite Anode Cells----------------------193

4.3.8

Key Performance Indicators for Si/C Composite Anode Application-----------------194

4.4 Polymer-Based ASSB

4.4.1 Configuration of

Polymer-Based ASSB-----------------------------------------------------195

4.4.2

Considerations in Battery Structure-------------------------------------------------------196

4.4.3 Considerations in Battery Production-----------------------------------------------------197

4.4.4 Key Performance Indicators of

Polymer-Based ASSB -----------------------------------198

4.5 Cell Energy Density

4.5.1 Assumptions for Each Material------------------------------------------------------------198

4.5.2 Gravimetric and

Volumetric Energy Density-----------------------------------------------200

4.5.3 Expected Scenarios and

Roadmap--------------------------------------------------------201

5. Manufacturing Technology of ASSBs

5.1 Lab-Scale Cell Fabrication

5.1.1 Powder Pressing Cell Fabrication-----------------------------------------------------------205

5.1.2 Three-Electrode Cell Fabrication----------------------------------------------------------207

5.1.3 Coin Cell Fabrication--------------------------------------------------------------------------208

5.1.4 ASSB by Japan NEDO -----------------------------------------------------------------------209

5.1.5 Pouch Cell Fabrication----------------------------------------------------------------------210

5.2 Cell Manufacturing

Technology

5.2.1 Advantages and Disadvantages

by Type of ASSB-----------------------------------------214

5.2.2 Manufacturing Methods by Type of Solid

Electrolyte-----------------------------------215

5.2.3 Characteristics and Pros & Cons of

the Latest Manufacturing Technologies-------216

5.2.4 Comparison of CIP, WIP, and HIP

Processes-----------------------------------------------217

5.2.5 Densification of Electrode/Electrolyte

Layers -------------------------------------------219

5.2.6 Stacking Manufacturing Technology-------------------------------------------------------220

5.2.7 Slurry/Solution Casting Manufacturing

Technology----------------------------------221

5.2.8 Extrusion Manufacturing Technology-------------------------------------------------------222

5.2.9 Tape Casting Manufacturing Technology------------------------------------------------223

5.2.10 Electrolyte Infusion Manufacturing

Technology--------------------------------------224

5.3 Manufacturing Technology for

Oxide-Based Cells

5.3.1 Sintering ------------------------------------------------------------------------------225

5.3.2 Hot Pressing -------------------------------------------------------------226

5.3.3 Spark Plasma

Sintering(SPS)----------------------------------------------------227

5.3.4 Cold Sintering Process (CSP)-------------------------------------------------------------------228

5.3.5 Microwave Sintering-------------------------------------------------------------------------230

5.3.6 Ultra-Fast High-Temperature

Sintering------------------------------------------------------231

5.3.7 Flash Sintering--------------------------------------------------------232

5.3.8 Photon Sintering and Laser Sintering--------------------------------------------------------233

5.4 Dry Processing Technology

5.4.1 Issues in Wet-Based

Electrode Manufacturing Processes-----------------------------234

5.4.2 Advantages of Introducing Dry

Processing--------------------------------------------235

5.4.3 Key Dry Coating Technologies ----------------------------------------------------------------236

5.4.4 Free-Standing Electrode

Manufacturing Technology------------------------------------237

5.4.5 Direct Calendaring Manufacturing

Technology--------------------------------------------238

5.4.6 Composite Electrode and Separator

Fabrication----------------------------------239

5.4.7 Trends in Dry Process Adoption by

Major Companies-----------------------------------240

5.4.8 Comprehensive Comparison of Dry vs.

Wet Process Technologies-------------------241

5.4.9 Patent Trends in Dry Electrode

Processing------------------------------------------------242

5.5 Cell Manufacturing Process

5.5.1 Comparison of Manufacturing

Processes: All-Solid-State vs. Lithium Metal vs. Li-Sulfur-------------------------------------------243

5.5.2 Comparison of Manufacturing Processes:

Sulfide-Based vs. Oxide-Based vs. Polymer-Based--------------------------------245

5.5.3 Cathode Manufacturing-------------------------------------------------------------------------246

5.5.4 Anode Manufacturing---------------------------------------------------------------------------252

5.5.5 Anode Foil Manufacturing Process---------------------------------------------------------256

5.5.6 Solid Electrolyte Separator

Manufacturing Process Flow-------------------------------262

5.5.7 Cell Assembly----------------------------------------------------------------------------266

5.5.8 Advantage/Disadvantage Comparison by

Manufacturing Process-------------------271

5.6 Cell Manufacturing Methods

5.6.1 Limitations of Flat Press and

Roll Press ----------------------------------------------------274

5.6.2 Difference Between HIP and Hot

Pressing -------------------------------------------------275

5.6.3 Advanced Assembly Methods for

Lithium-Based Batteries-----------------------------276

5.6.4 Comparison Between Conventional

Sintering Methods and HIP-Treated Solid Electrolytes---------------------------------------278

5.6.5 Wet Manufacturing Methods for Cathode

Materials--------------------------------280

5.6.6. Surface Coating of Cathode Active

Materials----------------------------------------------283

5.6.7 Interface Enhancement Between Cathode

and Solid Electrolyte--------------------286

5.6.8 Protective Coating Layer for Cathode-----------------------------------------------------287

5.6.9 Composite/Coating Treatment of Active

Materials---------------------------------------288

5.6.10 Methods for Improving Cell

Characteristics---------------------------------------------289

6. Trends in Manufacturing Technologies of Major Companies

6.1 TOYOTA

6.1.1 Identification of Factors

Leading to Degradation in ASSB Cells-----------------------296

6.1.2 Issues of Performance Degradation in

Long-Term Cycles------------------------------297

6.1.3 TOYOTA’s Steps for Applying ASSB-----------------------------------------------------300

6.1.4 ASSB Manufacturing: Application of Pressing--------------------------------------------301

6.1.5 ASSB Manufacturing: Application of

Sublimation Fillers-------------------------------304

6.1.6 Application of Hot Isostatic Pressing

(HIP)------------------------------------------------ -305

6.1.7 Application of Resin Packaging---------------------------------------------------------------307

6.1.8 ASSB Cell Manufacturing and Assembly

Processes---------------------------------------312

6.1.9 Solutions and Measures for Enhancing

Battery Characteristics----------------------313

6.1.10 Comparison of Materials with Other

Batteries------------------------------------------314

6.1.11 Material Change from LIB to ASSB-----------------------------------------------------------315

6.1.12 Patent Analysis of TOYOTA’s ASSB

Manufacturing Process --------------------------316

6.2 HONDA

6.2.1 ASSB Manufacturing Methods-----------------------------------------------------------------318

6.2.2 Directions for ASSB Manufacturing----------------------------------------------------------319

6.2.3 ASSB Cell Prototype Manufacturing

Process---------------------------------------------320

6.2.4 ASSB Manufacturing Process: Mixing,

Electrode Coating-------------------------------321

6.2.5 Electrode Roll Pressing/Slitting ---------------------------------------------------------------322

6.2.6 Bonding Roll Pressing, Stacking----------------------------------------------------323

6.2.7 Tab Welding, Assembly, Sealing, Aging,

Inspection--------------------------------------324

6.2.8 Comprehensive EV Valuation Structure---------------------------------------------------325

6.2.9 Battery Development Roadmap-------------------------------------------------------------326

6.2.10 Responses to Next-Generation

Batteries------------------------------------------------327

6.2.11 Advantages of HONDA's ASSB----------------------------------------------------------328

6.2.12 Differences in HONDA's ASSB Process-----------------------------------------------------329

6.2.13 Detailed Measures for Production

Technology Development----------------------331

6.2.14 ASSB P/P Line Concept-----------------------------------------------------------------333

6.2.15 HONDA's ASSB Investment Plans-----------------------------------------------------------335

6.2.16 Overview of HONDA Tochigi Sakura

Factory----------------------------------------------336

6.2.17 Entire Process of HONDA’s ASSB------------------------------------------------------------338

6.3 Nissan

6.3.1 ASSB Manufacturing

Directions-------------------------------------------------------------340

6.3.2 Identification of Factors Leading to

ASSB Performance Degradation---------------342

6.3.3 Prototype Lab Manufacturing Process ----------------------------------------------------344

6.3.4 ASSB Manufacturing Process-------------------------------------------------------------------347

6.3.5 Nissan Solid Battery P/P

Line--------------------------------------------------------349

6.3.6 Nissan’s ASSB Development Schedule-----------------------------------------------------350

6.3.7 Nissan EV 36Zero

project-------------------------------------------------------------351

6.3.8 NCM-based Cathode and Lithium Metal

Anode Batteries----------------------------352

6.3.9 Introduction of Sulfide-based Solid

Electrolyte------------------------------------------353

6.3.10 Measures to Ensure Uniform Lithium

Deposition---------------------------------------354

6.3.11 Establishment of ASSB Production Line--------------------------------------------------355

6.4 Samsung SDI

6.4.1 ASSB Cell Configuration and Mass

Production Preparation----------------------------356

6.4.2 Reduction of Vehicle Weight and

Increase in Trunk Space------------------------------357

6.4.3 Safety and Pack Weight Reduction-----------------------------------------------------------358

6.5 LG ES

6.5.1 ASSB Development Roadmap and

Application Areas------------------------------------359

6.5.2 Development of Polymer-Based ASSB-------------------------------------------------------360

6.5.3 Development of Silicon-Based Anodes

for Sulfide-Based ASSB ----------------------361

6.5.4 Development of Anode-free Electrical

Technology for ASSB---------------------------362

6.6 Hyundai Motor

6.6.1 ASSB P/P Line Operations and

Development Status-------------------------------------363

6.6.2 Battery Manufacturing Using Roll

Presses of Different Diameters------------------364

6.6.3 Dry Electrode Manufacturing Using

Binder Fiberization--------------------------------365

6.6.4 Manufacturing of Anode-free ASSB----------------------------------------------------------366

6.6.5 High-Density ASSB Manufacturing

Using WIP---------------------------------------------366

6.7 CATL

6.7.1 ASSB Development Status----------------------------------------------------------------------368

6.7.2 CATL vs. TOYOTA Strategy Comparison------------------------------------------------------369

6.7.3 High-Performance Cathode Interface

Design----------------------------------------------370

6.7.4 CATL Electrolyte Strategy-----------------------------------------------------------------------371

6.8 Solid Power

6.8.1 ASSB Structure and Development

Line-up-------------------------------------------------372

6.8.2 ASSB Manufacturing Process------------------------------------------------------------------373

6.8.3 Si Anode, Li Anode EV ASSB Roadmap ------------------------------------------------374

6.8.4 ASSB Production Roadmap -------------------------------------------------------------------375

6.9 Kanadevia(Hitachi Zosen

Corporation)--------------------------------------------------------376

6.10 Mitsui Mining & Smelting ----------------------------------------------------------------------------378

6.11 Factorial Energy-----------------------------------------------------------------------------------------379

6.12 Blue Solution

6.12.1 Blue Solutions' LMP® ASSB

Structure -------------------------------------------------380

6.12.2 Blue Solutions' LMP® ASSB (Gen

4) Characteristics ------------------------------------381

6.12.3 Blue Solutions' LMP® ASSB (Gen

4) Target Characteristics ----------------------------382

6.12.4 Extrusion Manufacturing

Process and Ah-Level Production Process for Polymer-Based ASSBs -----------------------383

6.12.5 Blue Solutions' LMP® ASSB

Manufacturing Process -----------------------------------384

6.12.6 Blue Solutions' ASSB Roadmap --------------------------------------------------385

6.13 QuantumScape

6.13.1 QS ASSB Manufacturing Process

and Cell Characteristics-----------------------------386

6.13.2 QS ASSB Cell Specifications

and Performance-------------------------------------------387

6.13.3 QS ASSB Performance and

Roadmap-----------------------------------------------------388

6.13.4 Solid Electrolyte Separator

Production Technology: Cobra--------------------------389

6.13.5 Applied Product QSE-5 B ASSB-------------------------------------------------------------390

6.13.6 Introduction of Advanced

Production Equipment: Raptor----------------------------391

6.14 SES AI

6.14.1 SES Complete Cell Structure------------------------------------------------------------------392

6.14.2 SES Cell Performance and 103Ah

Cell Safety Test---------------------------------------393

6.14.3 SES Cell P/P Line Key Processes-------------------------------------------------------------394

6.15 ProLogium

6.15.1 ProLogium ASSB Cell

Structure-------------------------------------------------------------395

6.15.2 Ceramic Separator: CSE (Composite Solid Electrolyte –

Oxide + Solid Polymer Electrolyte)---------------396

6.15.3 ProLogium ASSB Line

Configuration and Trends-------------------------------------398

6.15.4 ProLogium ASSB Key

Manufacturing Processes-----------------------------------------399

6.16 Johnson Energy Storage

6.16.1 Cell Information and

Related Characteristics--------------------------------------------400

6.16.2 Slurry Coating Process--------------------------------------------------------------------401

6.16.3 Co-Extrusion Process----------------------------------------------------------------------403

6.17 TaiyoYuden(太陽誘電)

6.17.1 MLCC Type ASSB Structure---------------------------------------------------------405

6.17.2 MLCC Type ASSB Manufacturing Process------------------------------------------------406

6.18 TDK--------------------------------------------------------------------------------------------------------410

6.19 TDL--------------------------------------------------------------------------------------------------------411

6.20 Nippon Electric Glass (NEG)-------------------- -----------------------------------------------------413

6.21 Sevenking Energy-------------------------------------------------------------------------------------414

6.22 Solivis

6.22.1 Company Overview, Performance,

and Notable Information--------------------415

6.22.2 Solivis Solid Electrolyte Development----------------------------------------------------416

6.22.3 Sulfide-Based Solid

Electrolyte Hengsheng 1st Factory Groundbreaking---------417

6.22.4 Solivis Solid Electrolyte

Product Line: SICON Series 3 Types------------------------418

6.23 NANBOCAMP

6.23.1 NANOCAMP History---------------------------------------------------------------------------419

6.23.2 Argyrodite Oxysulfide Solid

Electrolyte Development-----------------------------420

6.23.3 Manufacturing Process

Establishment and Characterization-------------------------421

6.23.4 Cell Evaluation System

(Evaluation System from Raw Materials to Cells)-------- -422

6.23.5 Plant Completion, Facility

Expansion and Construction-------------------------------423

6.23.6 Production Capacity, Revenue,

and Customer Order Supply-------------------------424

6.24 ENFLOW

6.24.1 Enflow History and Plant

Status-------------------------------------------------------------425

6.24.2 Spray Pyrolysis Process and Spherical

Fine Powder Production Method-------426

6.24.3 Scale-Up Plan and Commercialization----------------------------------------------427

6.25 Umicore

6.25.1 Umicore’s Roadmap for

Cathode materials ----------------------------------------------428

6.25.2 Umicore’s All-Solid-State Cathode

Active Material IP Portfolio-----------------------429

6.25.3 Umicore’s Battery Development

Progress---------------------------------------------430

6.25.4 Breakthrough in ASSBs through

Catholyte------------------------------------------------431

6.26 Panasonic----------------------------------------------------------------------------------------432

6.27 Lotte Energy Materials-----------------------------------------------------------------------------433

6.28 Idemitsu-----------------------------------------------------------------------------------------434