<2025> Technology Trends and Market Outlook of LIB Separators (~2035)

Lithium-ion batteries play a crucial role

in various sectors, including electric vehicles (EV), energy storage systems

(ESS), and consumer electronics (CE). Consequently, continuous improvements in

energy density, lifespan, and safety are essential. In meeting these demands,

separators are gaining attention as a critical component that determines

battery performance and stability. Separators allow ion transport through the

electrolyte while preventing physical contact between the cathode and anode,

thereby avoiding internal short circuits. Although classified as an inactive

component, the thermal, mechanical, and electrochemical properties of

separators significantly influence the cell's stability, lifespan, and safety.

Today, separator technology is advancing

through the development of various materials and processes. Conventional

polyolefin-based separators (PE, PP) are widely commercialized due to their

excellent mechanical stability and thermal resistance. However, they exhibit

performance limitations under high-power and high-temperature conditions. To

address these challenges, ceramic coating technologies and nonwoven-based

separators have been introduced, significantly improving thermal stability and

durability. Additionally, the emergence of next-generation batteries, such as

solid-state batteries, necessitates the design of new composite separators that

surpass the limitations of conventional ones. In particular, separators

utilizing PVDF (polyvinylidene fluoride) and other advanced polymer materials

are being actively researched for their superior thermal stability and

electrochemical performance, aligning with the requirements of next-generation

batteries.

With the technological advancements in

separators, the LIB market is experiencing rapid growth. According to SNE

Research, the global separator market is projected to grow from approximately

$2.2 billion in 2025 to $12.8 billion by 2030, achieving a CAGR of over 12%.

This growth is primarily driven by the expansion of electric vehicle adoption

and the increasing demand for energy storage systems (ESS). In particular, the

demand for high-performance batteries is acting as a catalyst for innovations

in separator technology. Simultaneously, major manufacturers are accelerating

the development of separators tailored to next-generation battery technologies,

such as solid-state batteries.

The 2025 report provides a comprehensive

analysis of LIB separator technologies and the market. It delves into the

development trends and performance enhancement strategies for key materials

such as PE, PP, and PVDF. Additionally, it offers an in-depth examination of

the evolution of ceramic coating and composite separator technologies, which

have recently garnered significant attention. The report includes historical

demand data from 2021 to 2024 based on global market data and presents market

forecasts from 2025 to 2030. It also highlights the latest product trends and

technological strategies of major separator manufacturers, offering valuable

insights into the present and future of the LIB industry.

Separators have emerged as a critical

component that determines the performance and safety of lithium-ion batteries

(LIBs), going beyond being a mere part. This report provides technical insights

and market forecasts for researchers and industry professionals, serving as an

essential guide for comprehensively understanding the present and future of LIB

separators. As the LIB industry continues to evolve, the significance of

separator technology will grow even further in achieving environmental

sustainability and the goals of a circular economy.

Strong Points of This Report :

1. Comprehensive overview and technical

details of separators

2. Latest technological development trends

in separators

3. Market forecast data for separators

4. Detailed information on manufacturing

and product status of major separator companies

Contents

Report Overview

1. Current Status and Development Trends of Separator Technology

1.1 Introduction 14

1.1.1 Current Status of Separator

Development

1.1.2 Role of Separator

1.2 Types of Separator 18

1.2.1 Microporous Polyolefin Separator

1.2.2 Nonwoven Fabric

1.2.3 Ceramic Composite Separator

1.3 Separator Characteristics 28

1.3.1 Chemical Stability

1.3.2 Thickness

1.3.3 Porosity

1.3.4 Pore Size

1.3.5 Torsional Rigidity

1.3.6 Air Permeability

1.3.7 Lithium-ion Permeability

1.3.8 Mechanical Strength

1.3.9 Wettability

1.3.10 Electrolyte Absorption

1.3.11 Thermal Shrinkage

1.3.12 Shutdown Characteristics

1.3.13 Cost

1.3.14 Oxidation Stability

1.3.15 Melt-down

1.4 Major Issues of Separator 41

1.4.1 Separator Properties

1.4.2 Swelling and Softening of Separator

1.4.3 Separator Damage by Lithium Dendrite

1.4.4 Thermal Damage

1.4.5 Mechanical Damage

2. Polyolefin-Based Separator

2.1 Polyolefin-Based Separator

Manufacturing Process 44

2.1.1 Dry Method

2.1.2 Wet Method

2.2 Relationship Between Polyolefin-Based

Separator and Battery 52

2.2.1 Battery Performance

2.2.2 Battery Safety

2.3 Latest Development Trends of

Polyolefin-Based Separator 58

2.3.1 Surface Treatment

2.3.2 Polymer-Functionalized Polyolefin

Separator

2.3.3 Ceramic-Coated/Deposited Polyolefin

Separator

2.3.4 Ceramic/Polymer-Functionalized Hybrid

Polyolefin Separator

3. Nonwoven Fabric Separator

3.1 Nonwoven Fabric Separator Manufacturing

Process 64

3.1.1 Dry-laid Method

3.1.2 Wet-laid Method

3.1.3 Spun-bond

3.1.4 Melt-blown Process

3.1.5 Web Bonding

3.2 Properties of Nonwoven Fabric Separator 73

3.3 Latest Development Trends of Nonwoven

Fabric Separator 76

3.3.1 Cellulose-Based Separator

3.3.2 Fluoropolymer-Containing Separator

3.3.3 PVA Separator

3.3.4 PAN Separator

3.3.5 PET Separator

3.3.6 PI Separator

3.3.7 PEI Separator

3.3.8 Nylon Separator

3.3.9 PEEK Separator

3.3.10 PMMA Separator

3.3.11 PBI Separator

3.3.12 Poly(Para-Phenylene Benzobisoxazole)

Separator

3.3.13 Poly(m-Phenylene Isophthalamide)

(PMIA) Separator

3.3.14 Polyphenylene Sulfide Separator

3.3.15 Polyphenylene Oxide Separator

3.3.16 Polysulfone Separator

4. Latest Technological Trends in

Heat-Resistant Coated Separators

4.1 Multilayer Structure Heat-Resistant

Separator 93

4.2 Nonwoven Fabric Separator 94

4.3 Inorganic-Introduced High-Safety

Separator 100

4.3.1 Non-Aqueous Inorganic Coated

Separator

4.3.2 Aqueous Inorganic Coated Separator

4.3.3 Binder-Free Separator

4.3.4 Multifunctional Inorganic Coated Separator

4.4 Heat-Resistant Polymer Coated Separator 114

4.4.1 Coated Separator with Heat-Resistant

Polymer and Inorganic Materials

4.4.1.1 Inorganic Coated Separator Using

Heat-Resistant Polymer as a Binder

4.4.1.2 Inorganic/Heat-Resistant Polymer

Coated Separator

4.4.2 Flame-Retardant Separator

4.4.2.1 Separator Made with Flame-Retardant

Materials

4.4.2.2 Separator with Additional

Flame-Retardant Materials

4.5 Microporous Polymer Separator 125

4.6 Thermal Shutdown Separator 130

4.7 Voltage-Sensitive Separator 133

5. Latest Technological Trends in Other

Separators

5.1 Ceramic Composite Separator 136

5.2 Nature-Inspired LIB Separator 137

5.3 Redox-Active LIB Separator 138

5.4 Shutdown-Functionalized LIB Separator 139

6. Latest Technological Trends and Developments in the Domestic LIB Separator Industry

6.1 Case Study 1: SKIET Wet Separator Sheet

Technology 141

6.1.1 Overview of Separator Sheet Line

Process

6.1.2 Basic Required Properties of

Separator Sheet

6.1.3 Overview of Separator Coating Process

6.1.4 Basic Required Properties of Coated

Separator

6.2 Case Study 2: W-Scope Wet Separator

Technology 147

6.2.1 Current Status of Wet Separator

Development

6.2.2 Development Direction of Wet

Separator

6.3 Case Study 3: EnerEver Separator

Coating Technology 151

6.3.1 Overview of Separator Coating

Technology Development

6.3.2 Prospects for Separator Coating

Technology Development

6.4 Case Study 4: Upexchem Dry Separator

Technology 159

6.4.1 Overview of Separator Technology

Development

6.5 Summary of Latest Technological Trends 160

6.5.1 Enhanced Heat Resistance and Safety

6.5.2 Ultra-Thin Separators

6.5.3 Use of Advanced Materials

6.5.4 Innovations in Manufacturing Process

6.5.5 Additional Factors in Technology Development

7. Separator Market Trends and Outlook

7.1 Current Status of Separator Demand 164

7.1.1 Regional Separator Demand Status

7.1.2 Material-Based Separator Demand

Status

7.1.3 Application-Based Separator Demand

Status

7.2 Market Share and Shipment Trends by

Separator Suppliers 170

7.2.1 Market Share Trends by Separator

Suppliers

7.2.2 Shipment Trends by Separator Suppliers

7.3 Trends in Separator Purchasing Volume

by Major LIB Manufacturers 173

7.3.1 Samsung SDI (2020~2024E)

7.3.2 LGES (2020~2024E)

7.3.3 SK on (2020~2024E)

7.3.4 Panasonic (2020~2024E)

7.3.5 CATL (2020~2024E)

7.3.6 BYD (2020~2024E)

7.3.7 CALB (2020~2024E)

7.3.8 EVE (2020~2024E)

7.3.9 Gotion (2020~2024E)

7.4 Separator Production Capacity Outlook 234

7.4.1 Production Capacity Outlook by Type

7.4.2 Production Capacity Outlook by

Company

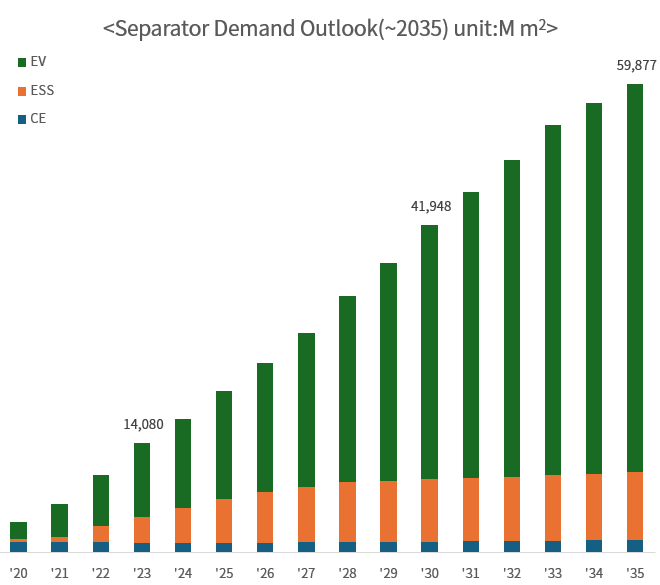

7.5 Separator Demand Outlook 236

7.5.1 Separator Demand Outlook by Region

7.5.2 Separator Demand Outlook by

Application

7.5.3 Separator Demand Outlook by Type

7.6 Separator Supply and Demand Outlook 242

7.6.1 Global Separator Supply and Demand

Outlook

7.6.2 Separator Supply and Demand Outlook

Excluding China’s Capacity

7.7 Separator Price Trends 244

7.7.1 Separator Price Structure

7.7.2 Separator Price Trends

7.8 Separator Market Size Outlook 247

8. Status of Separator Manufacturers

8.1 Korean Separator Manufacturers 249

8.1.1 SKIET (SK IE Technology)

8.1.2 W-Scope (WCP, W-Scope Corporation)

8.1.3 EnerEver

8.2 Japanese Separator Manufacturers 266

8.2.1 Asahi Kasei

8.2.2 Toray

8.2.3 Ube Maxell

8.2.4 Sumitomo Chemical (住友化学株式会社)

8.2.5 Teijin

8.3 Chinese Separator Manufacturers 285

8.3.1 SEMCORP (恩捷股份)

8.3.2 Senior (星源材质)

8.3.3 Sinoma (中材科技)

8.3.4 Gellec (金力股份)

8.3.5 ZIMT (中兴新材)

8.3.6 Huiqiang (惠强新能源)

8.3.7 Putailai (璞泰来)

8.3.8 Horizon (江苏厚生)

8.3.9 Bosser (博盛新材)

8.3.10 Lanketu (蓝科途)

8.3.11 CZMZ (沧州明珠)

8.3.12 Jinhui (金辉高科)

8.3.13 Green (中科科技)

8.4 Other Separator Manufacturers 344

8.4.1 Sepion Technology

9. Status of Separator Raw Material

Manufacturers

9.1 Korean Separator Raw Material

Manufacturers

9.1.1 KC

9.1.2 Osang Jaiel

9.2 Chinese Separator Raw Material

Manufacturers

9.2.1 Estone (壹石通)

9.2.2 CHALCO (中铝郑州有色金属研究院)

9.2.3 Sinocera (山东国瓷功能材料股份有限公司)

9.2.4 Tianma (河南天马新材料股份有限公司)

9.2.5 Higiant (邹平恒嘉新材料科技有限公司)

9.3 Other Separator Raw Material

Manufacturers

9.3.1 TOR Minerals

9.3.2 Nabaltec

10. References

|