Although

the recent slump in electric vehicle sales has slowed things down a bit, the

optimistic outlook for the electric vehicle industry remains.

As

each country strengthens its carbon emissions, automakers will not be able to

afford the penalties imposed by the regulations unless they sell electric

vehicles. Therefore, it is clear that the transition to electric vehicles will

continue. However, since consumers cannot lightly overlook the various negative

views of buyers regarding electric vehicles, electric vehicle manufacturers

have issues to solve, such as easy charging, long driving range, and safety

from battery fires. In particular, the issue of electric vehicle battery fires

is not a simple technical issue, but rather an important issue directly related

to social safety, so it cannot help but be thoroughly verified.

The

EU executive is planning to implement a new battery regulation in 2026, and the

core of this is the Battery Passport. Therefore, battery manufacturers also

need to strengthen battery safety and transparency to respond to international

regulations. Accordingly, this report will examine recent technology trends

in battery modules and packs for electric vehicles, and in particular, examine

the response measures and technologies of each manufacturer related to thermal

runaway.

This

report not only explains the basic concepts of secondary battery packs and the

basic concepts of thermal management, but also describes the battery pack

structure, development trends, and battery pack components, and also analyzes

and summarizes the development status of battery packs according to the major

OEM platforms, major EV electric vehicle battery pack specifications, trends in

battery thermal runaway response technologies, and a detailed description of

the thermal runaway prevention solution (Thermal Runaway Barrier), introduces

major battery pack component companies and thermal management, thermal runaway

companies, and provides an outlook on the EV market, pack market, and thermal

management material market. The last chapter covers the current status and

cases of related battery pack patent trends.

Strong

Points of This Report

① Easy to understand explanation of basic concepts of battery packs

and battery pack thermal management

② Easy to understand pack technology trends of major OEMs such as VW,

Hyundai, GM, CATL, BYD, LGES, Skon, Tesla, and NiO

③ Summary of major EV battery pack specifications (usable battery

pack capacity) and detailed analysis of sales price and energy density

④ Detailed analysis of battery thermal runaway response technology

trends and prevention solutions that have recently emerged as issues

⑤ Detailed information on development trends of domestic and foreign

battery pack component manufacturers and thermal runaway companies

⑥ EV market outlook, pack market outlook, and pack thermal management

material market outlook

⑦ Understanding pack patent trends through patent cases in pack

structural safety, thermal runaway, and CTP fields

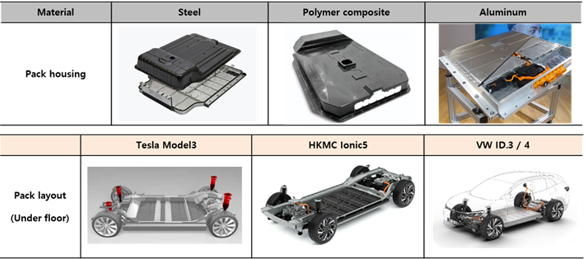

[

Battery pack components - pack housing materials ]

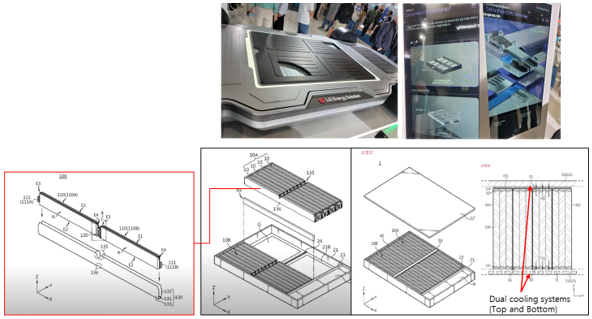

[Battery

pack development status according to OEM platform - LGES CTP Technology]

[Thermal Runaway Prevention Solution - TP (Thermal Propagation) Prevention Measures]

1.

Battery pack concept and definition -------------------------- 14

1.1 Basic concept of

battery pack

∙

Meaning of battery pack in electric vehicles

∙

Meaning of battery cell, battery module, and battery pack

∙

Electric vehicle platform and pack, module

∙

Basic configuration of pack in electric vehicle platform

∙

Cell and module connection method (Serial / Parallel)

∙

Battery capacity / Usable energy in battery

∙

Meaning of battery SOC, SOH, DOD

∙

Battery charge/discharge (C-rate)

∙

Battery pack specification

1.2 Thermal

management of battery pack -------------------------- 27

∙

Pack thermal management method

∙

Optimal pack thermal management (design factor)

∙

Cooling and heating method of pack

2. Battery pack structure

and development trends ------------------------- 38

2.1 Battery pack structure

∙

Pack structure (Exploded view)

2.2 Battery pack components

------------------------- 40

∙

Pack housing material

∙

Battery housing application status by xEV vehicle type (Cover, Tray)

∙

Pack Sealing Gasket

∙

Pack Integrity and Validation (CAE, IP test)

∙

CMA (Cell Module Assembly) structure (prismatic, pouch, cylindrical type)

∙

CMA Cover

∙

Compression pad

∙

Cooling system Type 1

∙ Cooling

system Type 2

∙ Cooling

system Type 3

∙ Cooling

system Type 4

∙ TIM(Thermal Interface

Material) configuration and characteristics by material

∙ TIM(Thermal Interface

Material) for module

∙ BMS(Battery Management

System) structure and characteristics

∙ PRA (Power Relay

Assembly)

∙ MSD (Manual Service

Disconnector)

∙ HVIL connector (High

Voltage Interlock connector)

∙ Sensors (Temperature and

current sensors)

2.3 Battery pack development status by

OEM platform ------------------- 64

∙

Concept change of pack by EV platform

∙

Pack features by EV platform

∙ VW’s

MEB platform

∙ Hyundai

Motor’s E-GMP platform

∙ GM’s

Ultium platform

∙ Technology

trends of module-free battery packs

∙ CATL,

BYD’s CTP Technology

∙ LGES’s

CTP Technology

∙ SK

on’s CTP Technology

∙ Tesla’s

New structural battery pack (Cell to Vehicle)

∙ Application

of Hybrid Battery Pack (NIO NCM-LFP

battery cell CTP)

∙ Application

of Hybrid Battery Pack (CATL AB battery

Pack)

3.

Electric vehicle battery pack specification analysis and summary ---------------------

78

3.1

Electric vehicle battery pack specification analysis

3.2

EV battery cell and pack sales price forecast

3.3

Passenger car electric vehicle battery pack average capacity (kWh)

3.4

Electric vehicle battery pack energy density analysis (kWh/kg)

3.5

Electric vehicle battery pack usable energy analysis

3.6

Weight ratio of major battery pack components

3.7

Cost composition of major battery pack components

3.8

Summary of major EV battery pack specifications 1

3.9

Summary of major EV battery pack specifications 2

3.10

Summary of major EV battery pack specifications 3 (Usable battery pack

capacity)

4.1

Thermal runaway phenomenon and causes

4.2

The need for battery pack flame retardancy

4.3

Thermal runaway prevention solutions (Thermal Runaway Barrier)

∙ TP (Thermal

Propagation) prevention measures

∙ TBA (Thermal

Barrier Assembly) applied inside the module

∙ TBA (Thermal

Barrier Assembly) applied outside the module

∙ Characteristics by

TP material

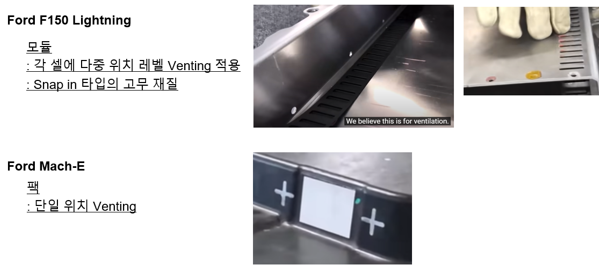

∙ TP solutions at

module and pack levels: Venting technology

∙ Two types of

battery pack venting solutions (Level 1, Level 2)

∙ General design of

battery pack venting (Level 1, Level 2)

∙ Vent application for

De-gas at cell, module and pack level

∙ Key design and

performance considerations

∙ Product requirements:

Level 1, Level 2 venting

∙ Test requirements

∙ Benchmark case analysis

∙ Insulating materials for

Thermal Barriers that can replace Mica

∙ Mica material properties

∙ TRP Paper product

properties

∙ Other alternative

materials

5. Battery Pack Major

Component Suppliers ------------------------ 125

5.1 Battery Pack Component Manufacturers

(Global / Domestic)

∙ KET

∙ Younghwa

Tech

∙ LS

EV Korea

∙ WOORY

INDUSTRIAL

∙ Hyunwoo

Industrial

∙ YURA

CORPORATION

∙ Kyungshin

∙ Mobase

Electronics (Seoyeon Electronics)

∙ Aluco

∙ Hanon

Systems

∙ Saint-Gobain

PPL

∙ INZI

CONTROLS

∙ SEBANG

GLOBAL BATTERY

5.2 Thermal management material manufacturers

∙ Alkegen

∙ Morgan

∙ Rogers

∙ Laird

∙ ASPEN

∙ Pamica

∙ Glory

6. EV & Pack Market

Outlook -------------------- 166

6.1 EV market outlook

∙ Global

passenger EV market outlook by BEV/PHEV

∙ Global

xEV battery demand and outlook

∙ Global

EV battery cell and pack market size

∙ Outlook

by global EV major maker

6.2 Pack market outlook

∙ Pack

market size and outlook for electric vehicles

6.3 Pack component market outlook

∙ Market

size outlook for electric vehicle pack components

6.4 Pack material market outlook

∙ Market

size outlook for pack housing materials

∙ Market

size outlook for pack thermal management materials

∙ Market

size outlook for TP solution materials

∙ Market

size outlook for cell-to-cell structure materials

6.5 Market size outlook for thermal management materials

7. Pack Patent Trends -------------------------

177

7.1 Status of domestic battery company

patent applications

7.2 Domestic battery company patent

cases

∙

Patent cases in the field of pack structural safety

∙

Patent cases in the field of pack thermal runaway