<2024> Global LFP Technology Trends and Market Outlook

In recent years, Lithium Iron Phosphate (LFP) batteries have gained remarkable momentum in the electric vehicle (EV) market, especially with significant uptake in China. With global automakers, including Tesla, showing increasing interest in LFP batteries, they are quickly becoming a central focus in EV battery innovation.

Why LFP Batteries Are Rising

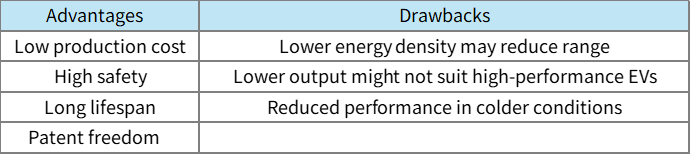

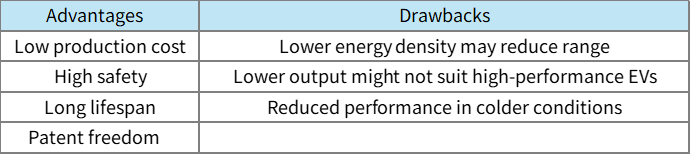

Cost Competitiveness: LFP batteries omit costly cobalt, reducing production costs significantly. Recent raw material price hikes have further highlighted their cost advantage.

Safety: LFP batteries maintain stable performance at high temperatures and during overcharging, significantly lowering the risk of fires.

Longevity: Their long life cycle extends battery replacement intervals, offering greater value.

Patent Expiration: With key patents expiring, production costs are further reduced due to the lack of licensing fees.

Advantages and Drawbacks of LFP Batteries

Future Development of LFP Batteries

Energy Density Improvement: Research on manganese-infused LMFP batteries is advancing to improve energy density.

Enhanced Output: Innovations are needed to support fast charging and high power output.

Improved Low-Temperature Performance: Enhancements to ensure stable performance in colder climates are underway.

Market Outlook

Given their cost efficiency and safety, LFP batteries are poised for a growing role in the EV market, especially in budget-friendly and commercial vehicle segments. This trend suggests a promising trajectory for LFP battery adoption.

Conclusion

LFP batteries are rapidly emerging as a cornerstone technology for EV mass adoption. With their cost efficiency, safety, and longevity, LFP batteries are expected to continue advancing as ongoing development efforts address their limitations.

In-Depth Analysis Topics Covered

Electrochemical background of LFP batteries

LFP battery manufacturing process technology

Market size and growth projections

Profiles of leading LFP battery manufacturers

Overview of LFP battery applications

Key Strengths of This Report

1. Technical Expertise: Provides an in-depth explanation of lithium iron phosphate and other lithium-ion cathode materials to enhance understanding of battery technology.

2. Material Comparison Analysis: Compares LFP materials with NMC materials, clearly highlighting each material's strengths and weaknesses.

3. Latest Technology Trends: Summarizes LFP manufacturing advancements and current technological developments, helping track industry shifts and future outlook.

4. Company Production Capabilities and Forecasts: Offers insights into production capacities of key players and future market outlook, aiding in competitive analysis and strategic planning.

5. Practical Insights: Equips companies and individuals entering the LFP market or initiating related research with essential information to identify business opportunities and guide R&D directions.

We believe this report will be a valuable resource for stakeholders in the EV industry.

1. LFP Market Outlook

1.1 Global EV Market Outlook

1.2 Global xEV Battery Market Outlook

1.3 Battery Market Outlook by xEV Type

1.4 LFP Battery Market Outlook by Region

1.4.1 China

1.4.2 Europe

1.4.3 North America

1.4.4 Others

1.5 LFP Battery Demand Outlook by Global OEM

1.5.1 TESLA

1.5.2 VW

1.5.3 HKMC

1.5.4 TOYOTA

1.5.5 Renault-Nissan

1.5.6 Stellantis

1.5.7 GM

1.5.8 Ford

1.5.9 BMW

1.5.10 Mercedes-Benz

1.5.11 Geely

1.6 ESS and LFP Battery Market Outlook

1.6.1 Global ESS Market Outlook

1.6.2 Global ESS Battery Market Outlook

1.7 Market Outlook of LFP Battery for EV/ESS

2. LFP SCM Analysis

2.1 Global LFP Cathode Material Supply and Demand Analysis

2.1.1 North American LFP Cathode Material Supply and Demand Analysis

2.2 LFP Cathode Material Price Forecast

2.3 LFP Battery Maker Supply Chain Analysis

2.3.1 2023 Battery Maker-Cathode Maker Collaboration Status

2.3.2 2024 Battery Maker-Cathode Maker Collaboration Status

2.4 Trends in China's Lithium Battery Value Chain

2.5 Status of LFP Cathode Material Manufacturers

2.5.1 Dynanonic

2.5.2 Guoxuan Hightech

2.5.3 LBM (Lopal technology)

2.5.4 Hunan Yuneng

2.5.5 Hubei Wanrun

2.5.6 BYD

2.5.7 Xiamen Tungsten(XTC)

3. LFP vs NCM Cost Analysis

3.1 China LFP Cost Trend

3.2 China NCM(523) Cost Trend

3.3 Korea NCM(523) Cost Trend

3.4 Comparison of China LFP& Korea NCM523 Cost

3.5 Comparison of LFP & NCM523 Cell Cost Structure

4. Expansion and Production Outlook of LFP Lines by Korean Battery Makers

4.1 LGES

4.2 SDI

4.3 SK On

5. Production Outlook of LFP by Korean Cathode Makers

- Ecopro BM, L&F, Posco Future M, LGC

6. LFP Battery Review

6.1 Basic Properties of LFP Cathode Materials

6.2 Basic Properties of LMFP Cathode Materials

6.3 Research Footprint on Improving Electrical Conductivity of LFP

6.4 Structure, Electrochemical Properties and Safety of LFP/LMFP

6.4.1 Structure, Electrochemical Properties of LFP/LMFP

6.4.2 Thermal Safety of LFP/LMFP

6.5 Summary of Patent Disputes on LFP

6.6 Comparison of Advantages and Disadvantages of LFP and NCM

6.7 Impact of Bus-Related Legislation

6.8 LFP Application Cases

6.8.1 Electric Buses

6.8.2 Electric Ships

6.8.3 ESS

6.8.4 UPS

6.9 Design of LFP Battery (CTP) and Module Standardization

6.9.1 Trends in Optimal LFP Battery Pack Design

6.9.2 LFP Battery Pack Price Information

7. LFP Battery Manufacturing Process

7.1 Development Trends in Lithium-Ion Secondary Batteries

7.1.1 LFP Manufacture Trend

7.1.2 Phosphate Precursor Production Process: Synthesis Method

7.1.3 Representative Mass Production Method for LFP

7.1.4 Precursor Production Process: Solid-State Method

7.1.5 Precursor Production Process: Co-precipitation Method

7.1.6 Precursor Production Process: Liquid Co-precipitation Method

7.1.7 Oxalate Iron Method (Solid-State)

7.1.8 Phosphate Method (Solid-State) Yield Method

7.1.9 LFP Manufacture Outlook

7.1.10 Ferric Oxide Method (Solid-State)

7.1.11 Hydrothermal Synthesis Method (Liquid)

7.1.12 LFP Manufacture facilities

8. LFP battery Patents

8.1 Solid-State Reaction

8.1.1 LG Chem

8.2 Precursor Method

8.2.1 Korea Research Institute of Chemical Technology

8.2.2 Korea National University of Transportation

8.2.3 Korea Research Institute of Chemical Technology

8.3 Freeze drying

8.3.1 Hyundai Motor

8.4 Ball Milling

8.4.1 Korea Polytechnic University

8.5 Conductive Polymer Coating Method

8.5.1 Ajou University

8.6 Fe(NO3)3 Method

8.6.1 Korea National University of Transportation