<2024> Li-S Battery Technology Development Status and Outlook

Lithium-Sulfur

(Li-S) batteries are lithium-ion secondary batteries (LIBs) that use sulfur or

sulfur compounds as cathode active materials, and often use metallic lithium or

its alloys for anode materials. Since sulfur can attract two lithium atoms or

release two electrons with one atom, it can theoretically achieve a gravimetric

energy density of 1675 mAh/g, which is about 10 times that of existing LIBs,

but in reality, development is underway aimed at realizing gravimetric energy

of about twice that.

Since

Li-S batteries do not use expensive metal materials such as cobalt or nickel,

their carbon footprint is 60% lower than that of general LIBs and 40% lower

than that of all-solid-state batteries, making them more eco-friendly to

produce. This has the potential to significantly improve battery performance,

making them a strong candidate for next-generation batteries that can

simultaneously provide low cost and improved performance.

Until now, the cycle life of

charging-discharging processes has often been as short as around 200 cycles.

This is primarily because sulfur from the cathode dissolves into the

electrolyte or forms polysulfides (Li2Sx), which do not revert to the original sulfur,

leading to rapid degradation of the original electrode structure. Additionally,

since sulfur itself is an insulator, a large amount of conductive additives is

needed for its use as a cathode, which has prevented the energy density from

reaching theoretical levels. Researchers have been tackling these issues

through extensive trial and error.

However,

in 2022, researchers from Drexel University in the U.S. reported achieving a

cycle life of 4,000 times. Development cases by battery manufacturers are also

increasing. For instance, the US company Lyten reported over 1,400 cycles for a

cell designed for electric vehicles in 2021. Additionally, Japanese company

ADEKA announced in November 2022 that they had achieved over 5,000 cycles at an

energy density of 100 Wh/kg and over 200 cycles at 450 Wh/kg. Furthermore, in

November 2023, ADEKA revealed a prototype cell with an impressive weight energy

density of 803 Wh/kg, the highest level ever achieved for lithium-ion

batteries.

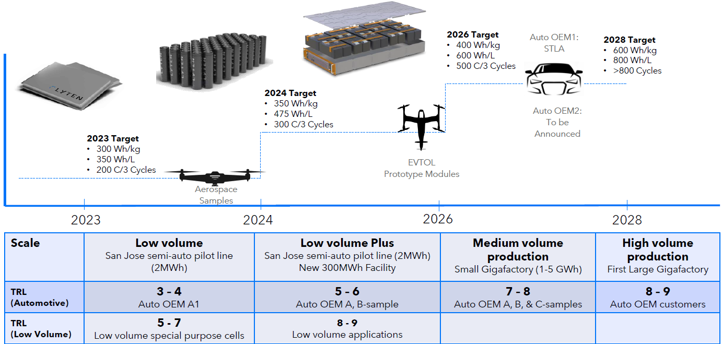

Recently, there

has been an active movement to provide samples to car makers. Lyten received

investment from European car maker Stellantis in 2023, and began shipping

pilot-produced cells to Stellantis in May 2024, and announced that it would be

shipping samples to more than 20 companies in late 2024. Currently, it is a

pouch-type cell, but it is said that cylindrical cells will also be

manufactured in late 2024. These can be manufactured at half the material cost

of existing LIBs, and the manufacturing yield is also said to be high at over

90%.

Li-S

Energy (Australia) started operating a pilot production line with a capacity of

2MWh/year in 2024. They are now planning to build a large-scale production

facility with a capacity of GWh per year.

In

2023, Gelion (UK) acquired the intellectual property of OXIS Energy, which went

bankrupt in May 2021. Using this technology, they announced a cell with an

energy density of 395 Wh/kg in April 2024 and plan to start sample shipments in

2026.

In

China, Zhongke Paisi Energy Storage Technology has been producing 35 Ah, 609

Wh/kg battery cells at a pilot scale since 2017 and is expanding production for

advanced solar drones, EVs, and power storage applications.

LG

Energy Solution, a global battery manufacturer, has also been researching Li-S as

one of next-generation batteries since 2015. By applying the pouch outer

material, introducing a new combination of electrolytes, and effectively

controlling the volume with the know-how accumulated over many years, the lifespan

has been increased, and it is intended for use in urban air mobility (UAM) and

high-altitude unmanned aerial vehicles (UAVs), and the goal is

commercialization in 2027. Meanwhile, in the case of high-altitude UAVs, it can

be used for 6 months with 200 times of charges, and it is said that the

condition required by the OEM is 400-500Wh/kg and used more than 200 times.

This

report provides a comprehensive overview of the development of Li-S secondary

batteries, including major technological advances, related technological

obstacles, and component/material developments. It also focuses on the latest

emergence of cell configurations that promise a leap forward in Li-S secondary

battery research. It also introduces advanced characterization techniques that

can help understanding the mechanisms involved in the chemistry of Li-S

secondary batteries, and provides an introduction to research programs in

various countries, covering the academic and practical applications of research

results to date.

Strong

Points of this report

① Summary of the concept of Li-S batteries and

historical development trends

②

Understanding of Li-S battery technical

obstacles and the status of component/material development

③ Latest trends in Li-S battery cell development

material composition

④ Presentation of Li-S battery application cases

by major companies

⑤

Introduction to the

status of Li-S battery-related patent applications and future development

directions

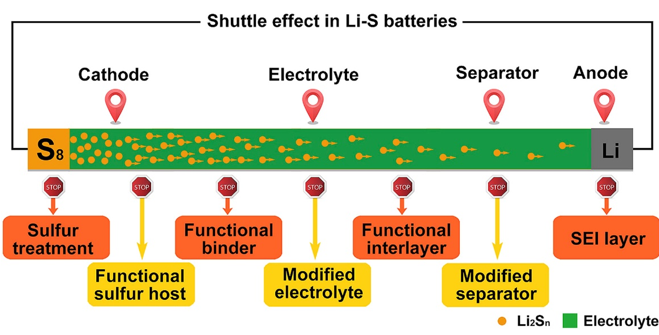

<Recent

advances in shuttle effect inhibition for Li-S batteries>

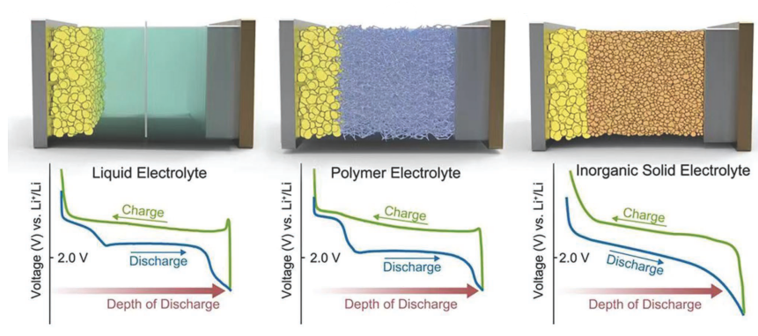

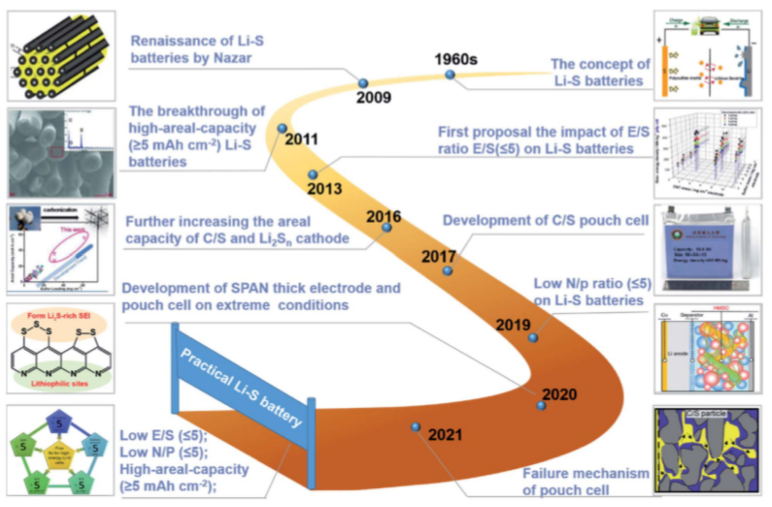

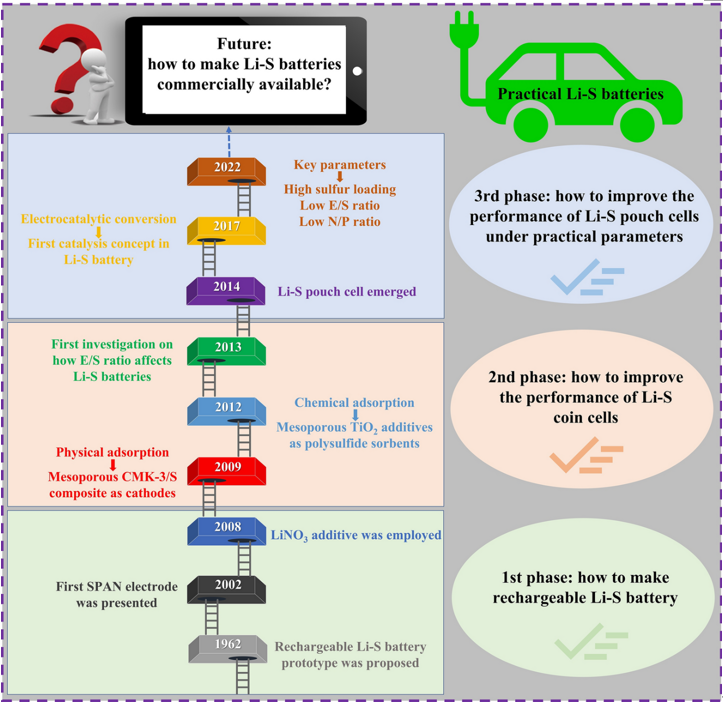

< Overview of Li-S battery development from concept

proposal to present & Roadmap for Li-S batteries >

< A brief timeline and key events in the development of Li-S batteries >

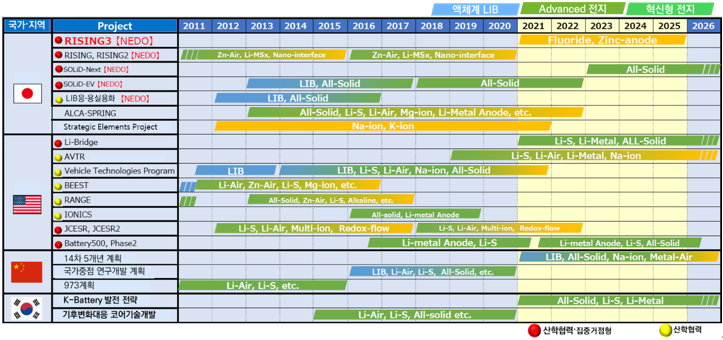

< Support projects for next-generation batteries_Li-S

batteries >

Table of Contents

1. Overview of

Lithium-Sulfur Secondary Batteries

9

1-1. Need for Lithium-Sulfur Secondary Batteries 9

1-2. History of Lithium-Sulfur Secondary Batteries 12

1-3. Principles of Lithium-Sulfur Secondary Batteries 16

1-4. Technical Issues of Lithium-Sulfur Secondary Batteries 21

1-4-1. Insulation of Sulfur

21

1-4-2. Formation of Dissolved Substances and Shuttle Effect 21

1-4-3. Formation of Insoluble Substances (Li2S) 25

1-4-4. Self-Discharge Phenomenon

25

1-4-5. Use of Lithium Anodes

28

1-4-6. Use of Thick Sulfur Electrodes 29

1-5. Commercialization of Lithium-Sulfur Secondary Batteries 30

1-5-1. Important Parameters for High-Energy-Density Lithium-Sulfur

Batteries 32

1-5-2. Industrialization of Lithium-Sulfur Batteries 35

2. Development

Status of Sulfur Cathode Technology for Lithium-Sulfur Secondary

Batteries 37

2-1. Traditional Sulfur Composite Electrode 37

2-2. Sulfur-Porous Carbon Composite Materials 38

2-2-1. Sulfur-Porous Carbon Composite Materials 38

2-2-1-1. Carbon Materials

39

2-2-1-2. Sulfur-Carbon Composite

39

2-2-1-3. Synthesis Methods

47

2-2-2. Sulfur-Graphene Composite Materials 50

2-2-2-1. Graphene and Graphene Oxide 50

2-2-2-2. Sulfur-Graphene/Graphene Oxide Composite 50

2-2-3. Binder-Free Sulfur-Carbon Composite Electrode 52

2-3. Sulfur-Graphene Composite Materials 55

2-3-1. Sulfur-Polyacrylonitrile Composite 55

2-3-2. Sulfur-Polypyrrole Composite

56

2-3-3. Sulfur-Polyaniline Composite

57

2-3-4. Other Sulfur-Conductive Polymer Composites 59

2-4. Binder-Free Sulfur-Carbon Composite Electrode 61

2-4-1. Metal Oxide Additives

61

2-4-2. Metal Oxide Coatings

62

2-4-3. Metal Sulfide Complexes 63

2-4-4. Intercalation Compounds 63

2-5. Catalyst Materials for Sulfur Cathodes 63

2-5-1. Metal Sulfide Catalysts 64

2-5-2. Metal Oxide Catalysts 66

2-5-3. Single-Atom Catalysts 68

2-5-4. Defect Site Catalysts 69

2-5-5. Quantum Dot Catalysts 71

2-5-6. Heterostructure Catalysts 72

2-5-7. Other Catalyst Materials 74

3. Development Status of Lithium

Sulfide (Li2S) Cathode Technology for Lithium-Sulfur Secondary Batteries

76

4. Development Status of Anode

Technology for Lithium-Sulfur Secondary Batteries 81

5. Current Status of Electrolyte,

Separator, and Binder Technology Development for Lithium-Sulfur Secondary

Batteries 97

6. Configuration of Lithium-Sulfur Secondary Battery Cell 125

6-1. Intermediate Layer

125

6-1-1.

Polysulfide Barrier Mechanism 126

6-1-2. Materials for the Intermediate Layer

127

6-2. Porous Current Collector 128

6-2-1. Sulfur Impregnation Strategy

129

6-2-2. Materials for Porous Current Collector 130

6-3. Sandwich Electrode 130

6-4. Dissolved Polysulfide Anolyte

131

6-5. Voltage Window of Lithium-Sulfur Secondary Battery 132

6-5-1. Upper Voltage Plateau

133

6-5-2. Lower Voltage Plateau 133

7. Analysis Techniques and Mechanistic

Understanding of Lithium-Sulfur Secondary Battery 133

7-1. In-Situ Analysis 134

7-2. Polysulfide Dissolution 135

7-3. Formation of Protective Layer 136

7-4. Kinetics 138

8. Development of All-Solid Lithium-Sulfur

Batteries 140

8-1. Summary 140

8-2. Current Status of LIBs 141

8-3. Necessity of All-Solid Lithium-Sulfur

Batteries 143

8-3-1. Safety Issues of LIBs 143

8-3-2. Increasing Demand for

High-Energy-Density Batteries 146

8-3-3. Raw Material Supply and

Sustainability Issues 148

8-4. Basics of All-Solid Lithium-Sulfur

Batteries 149

8-4-1. Sulfide-Based Solid Electrolytes 151

8-4-1-1. Glass Solid Electrolytes 151

8-4-1-2. Crystalline Materials 152

8-5. Sulfide-Based Cathodes 156

8-5-1. Sulfur 156

8-5-2. Metal Sulfides 158

8-5-3. Organic Sulfur 158

8-5-4. Li2S 159

8-6. Anode Materials for All-Solid

Lithium-Sulfur Batteries 160

8-6-1. Lithium Metal Anodes 160

8-6-2. Lithium Alloy Anode Materials 161

8-6-3. Silicon Anode Materials 162

8-7. Redefining Four Challenges of All-Solid

Lithium-Sulfur Batteries 162

8-7-1. Interface Stability 162

8-7-2. Lithium Dendrites 164

8-7-3. Volume Expansion and Electrochemical

Instability 166

8-7-4. Processing Issues 167

8-7-5. Regulatory Approval and

Standardization 167

8-8. Five Strategies for Accelerating

Commercialization of All-Solid Lithium-Sulfur Batteries 168

8-8-1. Performance Enhancement 168

8-8-2. Cell Design Improvements for Enhanced

Efficiency 170

8-8-3. Strategies for Large-Scale

Fabrication 172

8-8-4. Wet Coating Process 173

8-8-5. Dry Coating Process 174

8-8-6. Infiltration Process 175

8-9. Summary and Outlook 176

9. Energy Density Formula for

Practical Li-S Battery Design 177

10. Current Status of Lithium-Sulfur Battery

Development Companies 188

10-12. Zhongke

Paisi Energy Storage Technology Co., Ltd5

10-13. Shaanxi

Guoneng New Materials Co., Ltd(陕西国能新材料有限公司)67

11. Current Status of Major Patent Applications and Future Directions in

Technology Development 268

12. Recent Developments in Lithium-Sulfur Batteries 276

13. References 303