[2023] Lithium-ion Battery Electrolyte Technology Trends and Market Forecast (~2030)

Recently, the secondary battery market has

expanded from small IT applications to ESS and electric vehicles. Japanese companies such as Panasonic, which

developed secondary batteries and pioneered the industry, are losing out to

Korean powerhouses such as LGES, while Chinese companies such as CATL, BYD, and

CALB are further expanding their M/S with the support of the Chinese government

and an unlimited domestic market. Although the Korean, Chinese, and Japanese

"trilateral system" is expected to continue for the foreseeable

future, North America and Europe are also showing continued interest in the

large-capacity secondary battery manufacturing and materials market due to the

expansion of the electric vehicle market. In particular, the policies and

regulations of each country, such as the IRA, are expected to significantly

change the landscape of the secondary battery market.

The electrolyte is mainly composed of

solvents, lithium salts, and additives. Depending on the nature of the product,

the electrolyte will be developed in collaboration with lithium-ion secondary

battery manufacturers. For small IT-type products, the development period is as

short as three to four months, while electrolytes for xEVs are developed and

evaluated for more than a year. Excellent R&D capabilities are required to

develop and respond to various products according to customer needs.

In the past, the electrolyte market was dominated by Japan and South Korea, but with the recent rapid growth of Chinese companies, the top three market shares have been taken over by Chinese companies. In Korea, Donghwa Electrolyte, Soulbrain, and Enchem have been able to grow together as electrolyte suppliers with the three major lithium-ion secondary battery companies (Samsung SDI, LG Energy Solution, and SK energy). In Japan, Mitsubishi Chemical has diversified its portfolio of customers producing IT small, xEV medium and large cells. In China, Tinci, Guotai-Huarong, and Capchem dominate the market.

Lithium salts (LiPF6), the main

ingredient of electrolyte, have been mostly supplied by Japanese companies in

the past, but the game has changed as Chinese companies have increased their

CAPA. In South Korea, Foosung provides general-purpose lithium salts (LiPF6),

while Chunbo mass-produces specialized lithium salts (LiFSI, LiPO2F2,

LiDFOP, LiBOB). Additives are added during the electrolyte manufacturing

process to improve the lifespan and stability of Li-ion secondary batteries,

such as SEI protection, overcharge prevention agents, and conductive

properties. While Japanese companies dominate the additives market, in Korea

Chunbo and Chemtros are among the main suppliers.

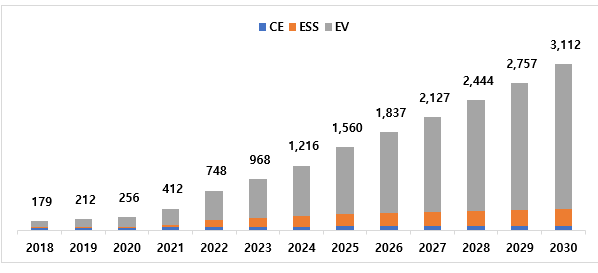

Electrolyte is one of the four key materials that make up a secondary battery. In the manufacturing cost composition of a typical Li-ion battery, the order of importance is anode material > separator > cathode material > electrolyte. To increase the energy density per unit cell, secondary battery manufacturers are increasing the input of anode and cathode materials, while reducing the input of electrolyte. However, from 2022 to 2030, the battery market is expected to grow at an average annual rate of around 23% (by capacity). The electrolyte market is expected to grow accordingly.

For large-scale rechargeable batteries for electric vehicles and ESS, the amount of electrolyte used is about 200 times to 4,000 times higher on a unit cell basis than for IT, so securing stability is becoming a particularly important issue. In addition to liquid electrolytes and gel polymer electrolytes (polymers) that are currently commercialized, research and development is underway to improve the stability of solid polymer electrolytes and all-solid ceramic electrolytes with excellent high temperature stability.

This report provides detailed technical

information on finished electrolyte products and their components for

application in lithium-ion secondary batteries and forecasts the demand and

market for binders based on our various forecasts to help readers understand

the overall scale.

Finally, by summarizing the electrolyte demand of major battery manufacturers and the supply status and outlook of electrolyte companies, the report aims to provide researchers and interested parties in this field with a wide range of insights from technology to market.

Strong points of this report

1. overall overview and technical information

on electrolyte finished products and components

2. Introduction to solid and polymer

electrolytes that will be applied to next-generation batteries other than

conventional LIBs

3. Provides objective data on the electrolyte

market outlook based on our forecast data

4. Detailed information on the product and

production status of major electrolyte players in Korea, China, and Japan

< Global

Electrolytes Market Demand Forecas (~2030)>

* Based on SNE battery

demand forecasts

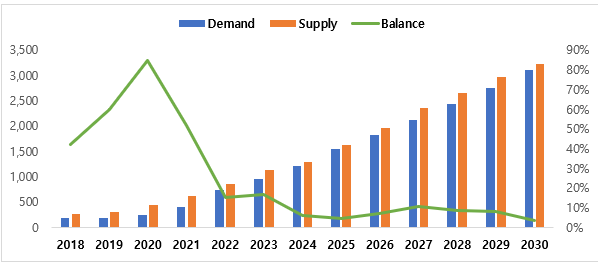

< Global Electrolyte Supply and Demand Outlook (2018~2030)>

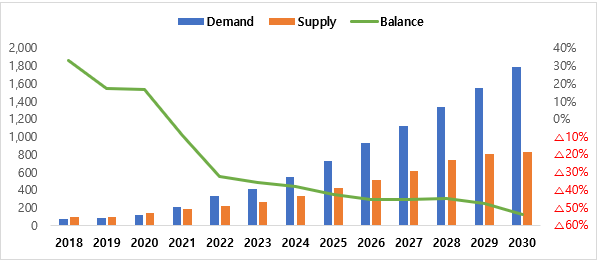

< Electrolyte Supply and Demand

Outlook for Non-Chinese Markets (2018~2030)>

* Except

for Chinese market supply and demand

[Index]

Outline of Report 7

Chapter Ⅰ. Electrolyte Overview

1.1 Understanding of electrolytes 10

1.2 Development trends and major

issues of electrolytes 13

Chapter Ⅱ. Development Trend of Liquid Electrolytes

2.1 Composition of liquid

electrolytes 35

2.2 Characteristics of liquid

electrolytes 56

2.3 Flame retardant material 72

Chapter Ⅲ. Development Trend of Polymer Electrolyte

3.1 Types of polymer electrolytes

101

3.2 Characteristics of polymer

electrolytes 113

3.3 Manufacturing method of

polymer electrolytes 121

Chapter Ⅳ. Solid Electrolytes

4.1 Necessity for development of

solid electrolytes 130

4.2 Types and technical

characteristics of solid electrolytes 133

4.3 Development trends of solid

electrolytes 135

Chapter Ⅴ. Latest Development Trends of Electrolytes

5.1 High voltage electrolyte

solvents 152

5.2 Lithium salts 159

5.3 Additives 173

5.4 Polyelectrolytes 200

Chapter Ⅵ. Electrolyte Solvents

6.1 Cyclic carbonate 205

6.2 Linear carbonate 209

6.3 Gas generation mechanism

by additives for forming the protective film on the electrode surface 216

Chapter Ⅶ. Electrolyte Additives

7.1 Electrolyte additives

for high-Ni cathode interface stabilization 226

7.2 Electrolyte additives

for improved output characteristics 232

7.3 Electrolytes using LiFSI

salts 235

7.4 Flame retardant additives

for improved thermal stability 237

7.5 Additives for

high-capacity anode interface stabilization 238

Chapter Ⅷ-1. Electrolyte Market Trends and

Outlook

8.1.1 Electrolyte demand by

country 240

8.1.2 Electrolyte usage by

application 242

8.1.3 Market status by

suppliers 244

8.1.4 Electrolyte demand by

LIB companies 252

(SDI/LGES/SKon/Panasonic/CATL/ATL/BYD/Lishen/Guoxuan(Gotion)/AESC)

8.1.5 Electrolyte demand

outlook 317

8.1.6 Electrolyte CAPA and

supply & demand outlook 318

8.1.7 Electrolyte price

trends 320

8.1.8 Electrolyte market

size forecast 324

Chapter Ⅷ-2. Electrolyte

Material Status

8.2.1 General lithium salts (LiPF6)

325

8.2.2 Non-LiPF6 lithium

salts 326

8.2.3 Functional additives 328

Chapter Ⅸ. Electrolyte Manufacturer Status

9.1 Korean electrolyte

companies 330

Dongwha Electrolyte /

Soulbrain / Enchem / Foosung / Chunbo / Chemtros

9.2 Japanese electrolyte

companies 375

Mitsubishi / Ube /

Centralglass / Tomiyama / MUIS / Nippon Shokubai

9.3 Chines electrolyte

companies 412

Tinci / Capchem / Guotai Huarong / Shanshan / Jinniu / DFD / Shinghwa